G.W.: 2,750 kg

Motor: 5 - 1/4 HP

Packing Measurement

(L x W x H : 261 x 167 x 170 )

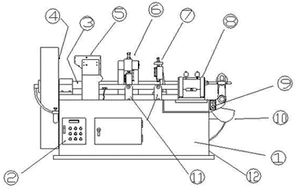

Features:

1.Pneumatic clutch control and electronic sensor allows for easy operation. The machine stops automatically in the event spokes are mis~fed or when spoke supply runs out.

2.Forced lubricating system on axles and rollers prevents abrasion of machine components, extending service life.

3.A specially treated steel plate is inserted into the head forging mold for improved durability and long operation life.

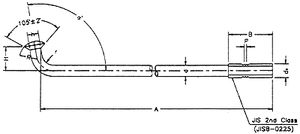

# |

d1

|

d2

|

05 |

05

H 0 |

0

h 0.2 |

a+2

|

R

|

r

|

P

|

Capcity

pcs/min. |

|

15

|

1.8

|

1.97~2.05

|

9

|

5.0

|

3.7

|

95

|

3.8

|

1.8

|

0.454

|

160~200

|

|

14

|

2.0

|

2.19~2.26

|

9

|

5.0

|

4.0

|

95

|

4.1

|

1.8

|

0.454

|

160~200

|

|

13

|

2.3

|

2.49~2.56

|

13

|

6.0

|

4.6

|

95

|

4.6

|

1.9

|

0.454

|

160~200

|

|

12

|

2.6

|

2.79~2.86

|

13

|

6.5

|

5.2

|

100

|

5.1

|

2.1

|

0.454

|

140~180

|

|

11

|

2.9

|

3.15~3.23

|

14

|

6.5

|

5.8

|

100

|

5.5

|

2.3

|

0.577

|

120~160

|

|

10

|

3.2

|

3.47~3.56

|

15

|

7.0

|

6.5

|

100

|

5.9

|

2.6

|

0.635

|

120~140

|

|

9

|

3.5

|

3.77~3.86

|

16

|

7.7

|

7.0

|

100

|

6.5

|

2.9

|

0.635

|

100~120

|

|

8

|

4.0

|

4.35~4.45

|

17

|

11

|

7.6

|

100

|

7.0

|

3.2

|

0.794

|

100~20

|

Spoke Making Process:

1.Setting the length guide for required spoke length, straightening the coiled steel wire with straightening shaft, conveying the straightened steel wire to cutting mold for cutting, and dropping the cut spoke wire into the spoke holder.

2.Spoke head forged by heading mold

3.Thread rolling

4.Unloading

Flow Figure:

|

1.

|

Cut spoke wire is put into the funnel

|

|

|

2.

|

Spoke head forging

|

|

|

3.

|

Bending

|

|

|

4.

|

Thread rolling

|

|

|

5.

|

Unloading

|